With Factory-X Into Digital Manufacturing - Without a Big Bang Transformation

How manufacturing SMEs benefit from modular solutions, retrofits and quick wins

Factory-X opens up the path to digital manufacturing for SMEs - modular, secure and economical. My blog article shows how small and medium-sized production companies can now benefit from retrofitting, data sovereignty and rapid success - without a complete IT overhaul.

Gradual Digitization Instead of Complete Conversion

Many SMEs are often skeptical about digital initiatives. The fear of costly IT upheavals, uncertain ROI and complex integrations is widespread. This is precisely where Factory-X comes in with a modular concept. Instead of a comprehensive rebuild, the initiative offers practical solutions that can be introduced step by step in line with specific use cases.

The goal:> Low-threshold but future-proof access to digital data rooms and Industry 4.0 standards. This makes digitalization plannable and feasible for small and medium-sized enterprises (SMEs) - and also cost-effective. At the same time, the modular structure offers flexibility: companies can select and combine individual modules depending on their level of digital maturity and strategic requirements - from pilot projects to scalable overall concepts.

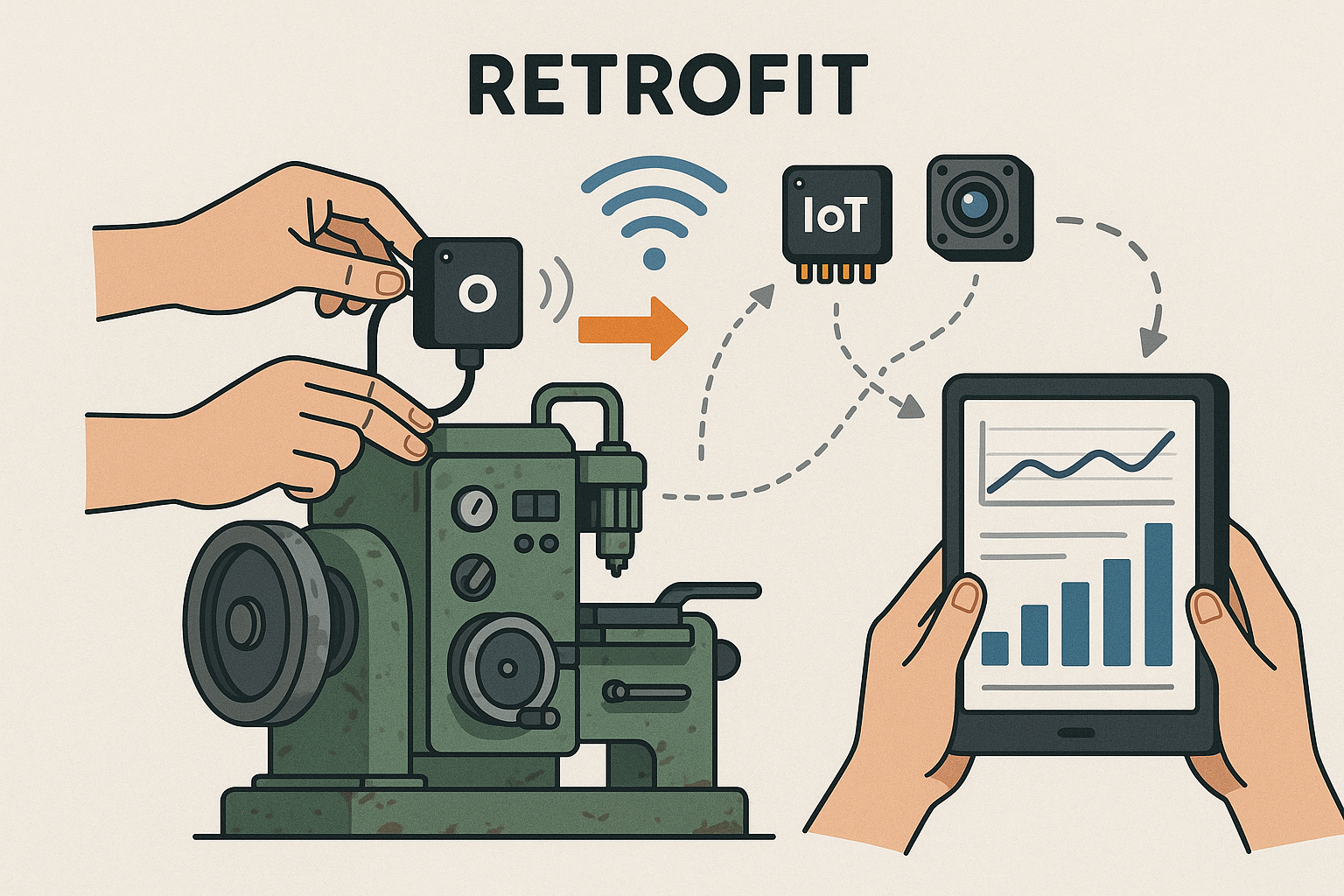

Retrofit: Use Existing Infrastructure

A common misconception: to participate in the Factory-X initiative, you need new machines or a cloud-native IT landscape. In reality, the opposite is true. The concept of retrofitting is a key element in integrating existing machinery into digital processes.

So-called starter sets - consisting of sensor technology, connectors and analysis software - enable machines to be connected quickly without having to make extensive changes to the existing IT. For brownfield factories in particular, this offers a realistic, scalable path towards digital sovereignty. Hybrid scenarios are also possible: new systems can be integrated directly, while existing ones follow step by step via retrofit solutions - with full interoperability thanks to open standards.

Data Sovereignty as a Central Principle

A key concern for many SMEs: Who controls my data when I connect? The architecture of Factory-X is explicitly decentralized and designed for data sovereignty and data sovereignty. Companies decide for themselves which data they share with whom - and under what conditions.

Technologies such as the Asset Administration Shell (AAS) (see also blog article: What is the Asset Administration Shell?), and the Eclipse Dataspace Connector (EDC) enable fine-grained control of access rights. This means that SMEs are no longer supplicants in digital platforms, but sovereign players in data exchange. Particularly important: the data remains with the owner - no central data storage, no unclear legal situation. This creates trust and the basis for new digital business models.

Quick Wins Through Targeted Use Cases

Perhaps the most important point is that Factory-X not only makes strategic sense, but also brings short-term operational benefits. The initiative comprises eleven specific use cases that address real-world manufacturing challenges.

The Following Use Cases of the Initiative Are of Particular Interest to SMEs

- Traceability (Usecase2.8): Improved transparency in the supply chain

- Energy and load management (Usecase2.9): Reduction of operating costs

- Information updates (Usecase2.2): Reduced effort for software maintenance

- Modular production (Usecase2.5): Faster adaptation to changing requirements

- On-Demand Manufacturing (Usecase2.6): Better capacity utilization through networking

These quick wins can often be realized within 6 to 12 months - a time frame that is also convincing within the company. Initial results then serve as "internal use cases" that can be used to support further digital projects.

Compliance as a Strategic Opportunity

Legal requirements are an increasingly pressing issue for manufacturing companies: CO2 transparency, digital product passport, supply chain due diligence obligations. Factory-X offers structures to not only meet these requirements, but also to generate competitive advantages from them.

Example: The "Carbon Footprint Management" use case helps companies to systematically record and report their emissions. This not only creates compliance, but also new opportunities for optimization and differentiation in the market. The integration of these functions into existing processes makes it easier for SMEs to efficiently implement regulatory requirements without having to develop their own special solutions.

Entry with Strong Partners

No SME has to go it alone. The Factory X environment offers a strong ecosystem of industry associations, research institutions and solution providers. Initiatives such as SCALE-MX or the Industry 4.0 platform offer practical entry aids and access to best practices.

Support is also available from the VDMA, the Open Industry 4.0 Alliance, the Gaia-X Hubs or the SmartFactory-KL. Government funding programs (e.g. via the BMWK) also help to lower investment hurdles. Access to such a network enables knowledge transfer, project support and risk minimization.

The important thing> is that it is not the technology that determines success, but the concrete benefits in operation. A good start begins with the identification of a clear bottleneck and a suitable, validated use case. If you prioritize wisely here, you save time and money - and increase the impact of digitalization in the long term.

Factory-X is not a lighthouse project for the big players - it is also an effective tool for medium-sized manufacturing companies. This sector in particular benefits from the modular, pragmatic approach. Those who start with retrofits and quick wins can shape digitalization at their own pace, build trust and create real added value.

The basic requirements:> A clear starting point, realistic scope and experienced partners. With this combination, SMEs can not only introduce Factory-X - but actively use it as a platform for growth and innovation.

Now is the time to take the first step. With clear orientation, strong partners and one goal: to secure our own competitiveness in a networked industry.

Written by

As Head of Strategic Business Development, Johannes Fuhrmann manages the portfolio and product development for the manufacturing industry, focusing on digital twins and data ecosystems. He previously worked at Deloitte and VELUX. He holds an MSc in Information Systems Management (University of Warwick) and a B.A. from HAW Hamburg.