Lean manufacturing: the basis for digitalization

Optimize and digitize processes

Rising costs and a shortage of skilled workers are threatening competitiveness - lean manufacturing can be the answer. Find out how you can use lean processes and intelligent IT to make your production efficient and future-proof, without any waste.

On September 3, we invite you to Cologne. You can look forward to inspiring impulses and best practices on digitalization, presented by industry experts and leading organizations.

Lean Manufacturing Meets Digital Transformation

The German SME sector is undergoing a "permanent stress test", which is often described as a VUCA world. But what does this mean in concrete terms? It is a market environment in which volatility, uncertainty, complexity and ambiguity make planning more difficult. Skills shortages, unstable supply chains and high energy costs are therefore forcing companies to take action. The solution often lies not in the purchase of new machines, but in more intelligent processes. This is precisely where lean manufacturing meets digital transformation.

It is clear to decision-makers in the industry that the mere digitalization of inefficient processes only leads to a "digitalization of waste". Real added value is only created when lean processes meet scalable IT.

What Is Lean Manufacturing?

Lean manufacturing, often referred to as lean production or "lean production", is more than just a method for reducing costs. It is a philosophy and systematic approach to minimize waste (Muda) without compromising productivity. Originally developed in the Toyota Production System (TPS), the approach aims to use production factors such as personnel, materials, equipment and time as efficiently as possible.

For modern IT service providers and manufacturers, this means a clear distribution of tasks today:

- Processual clean-up: First, non-value-adding activities are eliminated.

- Digital refinement: Companies then use data from ERP or MES to stabilize and control these streamlined processes.

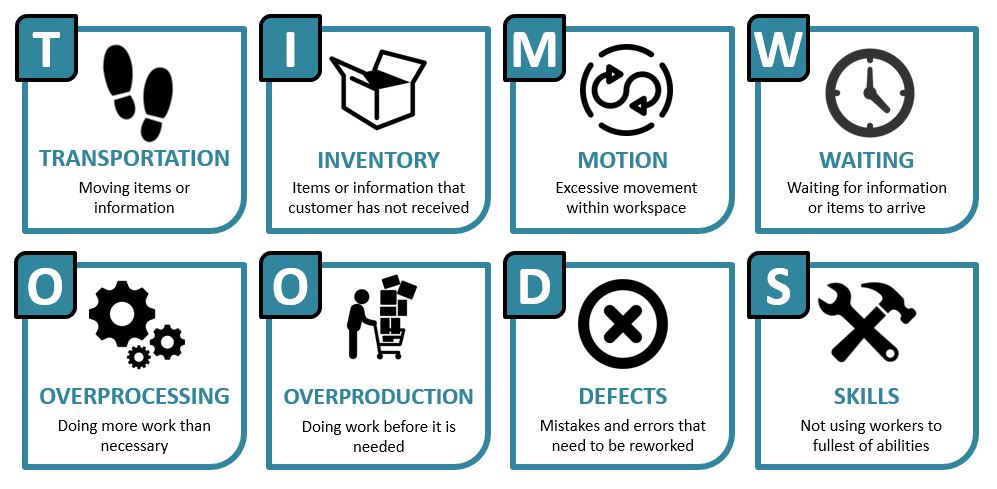

The 8 Types of Waste According to Lean

In order to create a seamless value stream to the customer without interruptions, waste must be reduced. In doing so, we come across an "enemy" that causes waste in organizational processes - and this is known by the acronym TIMWOODS. Each letter in TIMWOODS stands for a specific type of waste:

The 5 Principles of Lean Manufacturing

In order to successfully implement lean production, companies are guided by five central principles that form a cycle of continuous improvement:

- Define values (Specify Value): The value of a product is determined exclusively from the customer's perspective. Anything that the customer does not pay for, such as storage or waiting time, is considered a waste.

- Identify the value stream: This involves analyzing all steps from the raw material to the finished product. Today, tools such as Process Mining help to objectively map this process and make bottlenecks visible.

- Create Flow: The product should flow through the value chain without interruptions. The goal is "one-piece flow" instead of large batch sizes that only clog up the warehouses.

- Establish pull principle: Only what has actually been requested is produced. In contrast to the classic "push" principle, this avoids overproduction and high stock levels.

- Strive for perfection: Lean is not a one-off project, but a continuous improvement process (CIP or kaizen), as customer requirements are constantly changing.

Lean Manufacturing Methods: From 5s to Kanban

Theory is the foundation, but practice is the key to success. Today, classic lean methods can be excellently supported and even improved by IT solutions.

A classic example is the 5S method, which ensures order and cleanliness. In the digital factory, this is supported by apps for audits or digital tool tracking via RFID, because order is the basis for reliable data. Shop floor management (SFM) is also undergoing a fundamental change. Instead of static whiteboards with outdated key figures, leading companies are using digital dashboards. These display real-time data from the MES and make it possible to track problem solutions directly.

Another key element is the control of the material flow. While Kanban cards used to be inserted manually, today e-Kanban systems or RFID triggers automatically trigger orders in the SAP system. This prevents transmission errors and ensures smooth replenishment. To prevent errors (Poka Yoke), worker assistance systems are increasingly being used to guide employees step by step through the assembly process, thereby increasing process reliability.

Advantages of Lean Manufacturing for Your Company

Investing in lean manufacturing methods pays off strategically on several levels. Companies increase their liquidity, as the drastic reduction in inventories frees up tied-up capital. At the same time, quality improves as errors are detected immediately thanks to integrated control mechanisms.

In addition, lean processes have a direct impact on sustainability (Green Lean). Eliminating waste such as rejects or unnecessary transportation automatically reduces energy consumption and the carbon footprint. Last but not least, employees benefit: By eliminating monotonous routine activities and using supporting technologies, they are relieved and can concentrate on value-adding tasks.

Areas of Application: From the Hall to the Office

Lean is no longer limited to the automotive industry. In production, it helps to optimize set-up times, and in intralogistics, intelligent tugger trains are used instead of forklift trucks. But there is also potential in administration. In the "lean office", software robots (RPA) can take over repetitive tasks and thus massively speed up throughput times in administration.

FAQ: Frequently Asked Questions About Lean Manufacturing

-

What is the difference between lean manufacturing and Industry 4.0?

Lean ensures stable and efficient processes, while Industry 4.0 (digitalization) ensures scalability and speed. They are not opposites, but mutually dependent. Lean creates the necessary process stability, while digitalization ensures scalability.

-

Is lean production only for corporations?

No, SMEs in particular benefit enormously. As resources are often scarcer here, avoiding waste is essential for competitiveness and resilience.

-

Which IT systems support Lean?

Central to this are ERP systems for planning and MES for real-time control of production. Process mining for analysis and IIoT platforms for networking are becoming increasingly important. Integrating these systems via a "unified namespace" is crucial for a consistent data flow.

Conclusion

For IT service providers and manufacturing companies, the principle of "process first" applies. Only when processes are streamlined using lean principles can software solutions achieve their full ROI. The combination of lean methodology and IT excellence is the key to the smart factory.

Would you like to make your production more efficient? Analyze your value streams and check where digital tools can support your lean strategy.

Written by

As Head of Strategic Business Development, Johannes Fuhrmann manages the portfolio and product development for the manufacturing industry, focusing on digital twins and data ecosystems. He previously worked at Deloitte and VELUX. He holds an MSc in Information Systems Management (University of Warwick) and a B.A. from HAW Hamburg.