Smart Warehouse Evolution: The New Logistics Era

Connecting IoT, WMS and automation

The answer to the current challenges facing the logistics sector lies not in a mere technological upgrade, but in the strategic transformation to a smart warehouse. This evolution promises not only greater operational efficiency, but also a fundamental realignment.

Quintessence

- Explosive market growth: The smart warehouse market will grow from USD 26.10 billion (2024) to USD 98.64 billion by 2034 (CAGR 14.22%)

- Three technology pillars: Automation/robotics, IoT integration and cloud-based WMS form the foundation of intelligent warehouses

- Human factor remains central: Technology relieves repetitive tasks and creates value-adding roles in monitoring and data analysis

- Cybersecurity as a critical success factor: Networked systems require multi-layered security strategies and security-by-design approaches

- Stage-by-stage implementation recommended: Starting with cloud-based WMS systems and gradual expansion to include automation components

The German logistics industry is facing a paradigm shift. While the e-commerce boom is continuously increasing customer expectations in terms of delivery speed and precision, companies are also struggling with rising personnel costs, which can account for up to 80% of total costs in traditional warehouse systems. Added to this is the acute shortage of skilled workers, which is increasingly making manual warehouse processes a risk factor.

The answer to these challenges does not lie in a mere technological upgrade, but in the strategic transformation to a smart warehouse.

This evolution not only promises greater operational efficiency, but also a fundamental realignment of warehouse logistics towards a proactive, data-driven ecosystem.

Smart Warehouse: More than just digital modernization

A smart warehouse is defined as a highly integrated warehouse environment that seamlessly integrates advanced technologies and innovative management systems to digitize and automate internal processes. In contrast to the traditional warehouse, which primarily functions as a static storage location, the intelligent warehouse is characterized by its agility and real-time visibility of the entire operation.

This fundamental transformation is being driven by several market factors. The global smart warehouse market was estimated at USD 26.10 billion in 2024 and is expected to grow to USD 98.64 billion by 2034 - a robust compound annual growth rate of 14.22%. In parallel, the broader warehouse automation market is growing from USD 26.5 billion to a forecast USD 115.8 billion (CAGR 15.9%).

The Asia-Pacific region is leading this growth with an expected CAGR of up to 17.9%, while North America still dominates with a market share of 32%. These regional differences reflect different speeds of digitization and infrastructural starting conditions.

The three pillars of the Smart Warehouse architecture

Automation and robotics: precision through intelligent mechanics

The first pillar is formed by automation technologies ranging from traditional automated guided vehicles (AGVs) to highly developed autonomous mobile robots (AMRs). While AGVs navigate on predefined routes, AMRs are revolutionizing intralogistics with their flexibility: equipped with advanced sensor technology, they autonomously avoid obstacles and optimize their routes in real time.

Collaborative robots (cobots) in particular demonstrate the potential of human-machine interaction. They are explicitly designed for safe collaboration in shared workspaces and significantly increase productivity in hybrid environments. The "goods-to-person" principle illustrates this approach perfectly: robots bring required goods to the employee, who can concentrate on value-adding order picking.

By implementing AMR systems, a medium-sized retail company was able to reduce its throughput times by 35% and cut its error rate by 60% at the same time. These figures illustrate the transformative potential of modern automation solutions.

Humanoid robots: the flexible bridge between islands of automation

The next evolutionary stage of warehouse automation is ready: Humanoid robots (HR) will enter industrial mass production from 2025. The global market is expected to grow from 1.68 billion US dollars (2023) to up to 74 billion US dollars (2032) - with annual growth rates of between 34 and 45 percent.

Your strategic strength: HR closes critical gaps that conventional automation leaves open. They work seamlessly in existing environments optimized for humans - without costly infrastructure conversions. Systems such as "Digit" from Agility Robotics, already in use at GXO Logistics and Amazon, act as a flexible link between AMR, AGVs and conveyor belts. They take over the "last 10 meters" - those critical transfer points that traditionally require manual intervention. For German logistics companies, early pilot projects provide the decisive knowledge advantage.

The flexibility of humanoid robots only unfolds its full potential through intelligent networking. The Internet of Things forms the nervous system that connects all automation components - from AMR to humanoids to conveyor belts - to form a self-optimizing ecosystem.

IoT as a nervous system: real-time transparency through networked intelligence

The Internet of Things acts as the nervous system of the smart warehouse. IoT devices such as RFID tags, sensors and cameras continuously collect data and communicate without human intervention. This technology enables precise, real-time inventory management, where every item and every pallet can be precisely localized.

Sensors on machines and robots open up the possibility of predictive maintenance. By monitoring parameters such as vibration, temperature or energy consumption, impending failures can be detected at an early stage and expensive downtime prevented. In fleet management, IoT devices track vehicle locations and consumption data, which enables continuous optimization of routes and use of resources.

Cloud-based WMS: the intelligent brain of logistics

The Warehouse Management System is the central hub and the brain of the intelligent warehouse. A paradigm shift has taken place here: A move away from traditional on-premises systems towards cloud-based architectures, which offer considerable advantages.

Cloud WMS enable implementation within weeks instead of months, as there is no need for hardware and IT infrastructure investments. These systems are highly scalable and adapt flexibly to fluctuations in demand and seasonal peaks. Automatic updates and reduced total cost of ownership increase the attractiveness of these solutions.

The integration of artificial intelligence and predictive analytics in modern warehouse management systems is fundamentally revolutionizing warehouse management. Instead of reacting to bottlenecks, intelligent systems can anticipate them and proactively optimize stock levels. Cloud-based solutions such as platbricks® close digitization gaps in logistics and make advanced WMS functionality affordable for small and medium-sized companies.

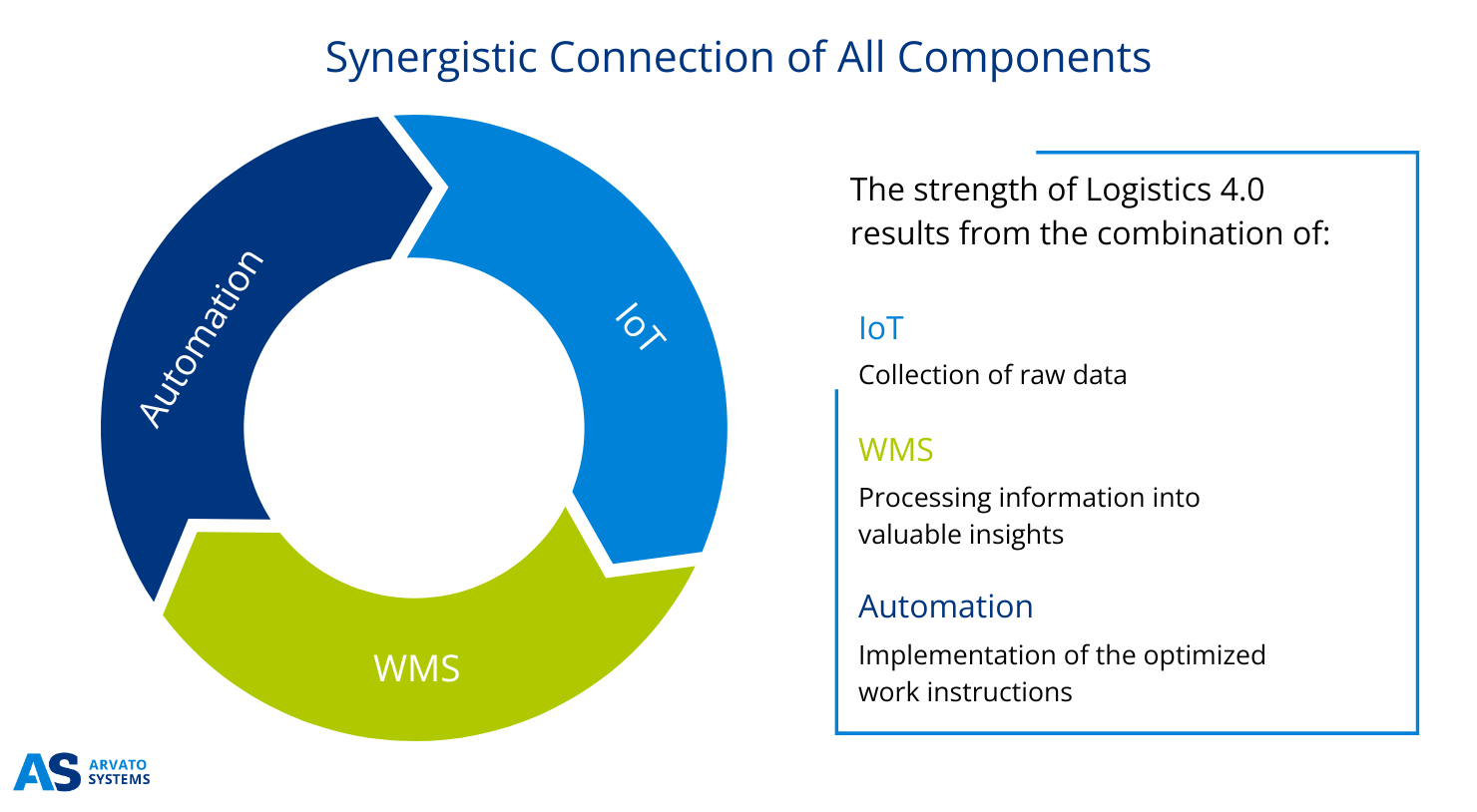

Synergetic networking: when technologies merge

The true strength of Logistics 4.0 lies in the synergetic networking of all components. IoT sensors continuously collect raw data and transmit it to the WMS. The system, often supported by AI, processes this information into usable insights and forwards optimized instructions to the automation systems.

This self-optimizing loop leads to continuous improvement: more data generates better decisions, which in turn enable more efficient physical processes.

People at the center of transformation

Contrary to widespread fears, the smart warehouse evolution is not aimed at eliminating people, but at repositioning them. Employees are relieved of physically strenuous, repetitive and monotonous tasks in order to concentrate on value-adding activities such as system monitoring, troubleshooting and data analysis.

However, this transformation requires a strategic reorganization of job profiles. The traditional role of warehouse worker is evolving into supervisor, technician or data analyst. New positions require skills in automation technology, PLC programming and data analysis. Targeted retraining programs to become an "electronic equipment mechanic in automation technology" or a "warehouse specialist" prepare the workforce for these requirements.

The use of wearables such as data glasses and exoskeletons as well as VR training simulations also increases productivity and safety. Sophisticated change management with open communication and targeted training transforms employees from observers into architects of change.

Overcoming challenges strategically

The transformation to a smart warehouse brings with it significant challenges that require strategic planning:

Investment costs and ROI assessment: High initial costs for automated systems require careful return-on-investment analysis. A staggered, phased approach can mitigate financial risk by starting small and gradually scaling implementation.

Legacy system integration: The compatibility of new technologies with existing, often outdated systems remains a complex challenge. Specialized partners are often necessary to bridge this technological gap.

Cybersecurity as an Achilles' heel: Networking creates expanded attack surfaces for cyber criminals. Ransomware attacks can paralyze entire supply chains, while insider threats and cloud vulnerabilities pose additional risks. A successful attack on an unsecured IoT device can spread to the entire system if network segmentation is poor.

A multi-layered security strategy with "security by design" principles is essential. Network segmentation isolates critical systems, continuous monitoring detects threats, and zero trust architectures verify every access. Employee training in dealing with phishing attacks remains a fundamental, often overlooked security factor.

Strategic recommendations for practice

Specific recommendations for action can be derived based on market developments and implementation experience:

- Stage-by-stage implementation approach: Start with a cloud-based WMS as the central control element. Gradually add automation components such as AMR or AGV to demonstrate the ROI step by step.

- Strategic partnerships: The complexity of the system requires in-depth specialist knowledge. Collaboration with experienced consultants and technology partners is essential to overcome integration hurdles and develop customized solutions.

- Invest in people: Successful transformation can only be achieved if people and technology work in harmony. Invest in targeted retraining programs and promote a corporate culture that actively supports change.

- Compliance and data protection: Take GDPR requirements and local compliance regulations into account right from the start. German companies are traditionally more sensitive to data protection, which must be reflected in the system architecture.

Future developments: 5G and predictive analytics

The next wave of innovation is being driven by 5G integration and advanced predictive analytics. 5G provides the ultra-reliable, low-latency communication for seamless IoT device networking and real-time robot control. Paired with advanced transport management systems, highly intelligent, self-optimizing ecosystems are created.

Sustainability is increasingly becoming a differentiating factor. Automation contributes to CO2 reduction through route optimization and energy efficiency, while digitalization enables increased resilience to supply chain disruptions.

Conclusion: Smart Warehouse as an enabler of Logistics 4.0

The smart warehouse is a central pillar of "Logistics 4.0". It not only revolutionizes warehouse processes, but also strengthens the entire supply chain through increased resilience, sustainability and competitiveness. The consistent integration of AI, big data and 5G technology will drive the next wave of innovation.

The key lies in the balance between technological innovation and human expertise. Companies that take a strategic approach to this transformation are positioning themselves for a more efficient, agile and secure future in logistics.

Written by

Bernd Jaschinski-Schürmann has been advising international companies in various industries for over 25 years, focusing on the optimization and digitalization of logistics and supply chain processes. He is responsible for the strategic development and expansion of digital supply chain solutions, in particular platbricks®.