Innovative Strength through Neutral and Cross-System Management of Machines and Devices

A demonstrator as a joint project from the LNI 4.0 - Testbed "Edge Management"

One goal of Industry 4.0 is to establish a fundamental connection between the world of information technology (IT) and operational technology (OT). Edge devices are an important component of this connection.

Edge Devices - The Basis for Interoperability

Edge devices enable interoperability and communication between all machines and the company's IT infrastructure. This forms the basis for

Essentially, an edge management system, or EMS for short, acts as an administration solution. At the SPS - smart production solutions trade fair in 2023, LNI4.0 and Arvato Systems presented an approach for the first time that combines the functionality of an EMS with the data standard of the digital administration shell (Asset Administration Shell, AAS for short), thus enabling manufacturer-independent edge management.

The necessary interoperability will result in numerous possible applications in the future. These include, among others

Integration of edge management systems into existing production processes through cross-manufacturer management of all machines

The main challenge lies primarily in the proprietary design of edge management systems. This means that each manufacturer's EMS is developed specifically for compatibility with the manufacturer's edge device. This in turn means that edge devices from different manufacturers are not able to communicate with each other. This also leads to fragmentation at an operational level within a company. This means that machines from different manufacturers have to be addressed via their predefined and isolated communication options in the context of maintenance, system updates and data exchange with the higher-level system. A lack of communication between the different systems thus promotes the formation of data silos. To counteract this problem, a comprehensive solution is required. An edge management system must be seen as a central instance. It enables the necessary interoperability and ensures the manufacturer-independent management of all edge devices in an industrial company. To achieve this, various manufacturers of edge solutions are working together as part of the "LNI 4.0 Edge Management Testbed".

LNI 4.0 Edge Management Testbed

Labs Network Industrie 4.0 is a pre-competitive association that brings together production companies and system providers in test centers. So-called 'testbeds' are one way of achieving this. These are scientific platforms for testing these ideas in predefined test environments. The aim of this explicit testbed is to test use cases for the management of edge and field devices via a device management system and to provide small and medium-sized enterprises with the results for networking their devices and to provide impetus for standardization. The partners involved work together to develop and test possible solutions. In this way, they develop innovative input for future standards. As a technology partner, Arvato Systems is responsible for the development of the EMS and related IT services, such as data management.

Illustration via Demonstrator

As part of the collaboration within the testbed, the LNI 4.0 Edge Management Demonstrator was developed, which represents a first prototypical industrial breakthrough across manufacturer boundaries. The Digital Asset Administration Shell (AAS) is of key importance here. The machines are mapped using IDTA-standardized AAS type plate information (asset modeling) to enable unique identification and management of machines and edge devices.

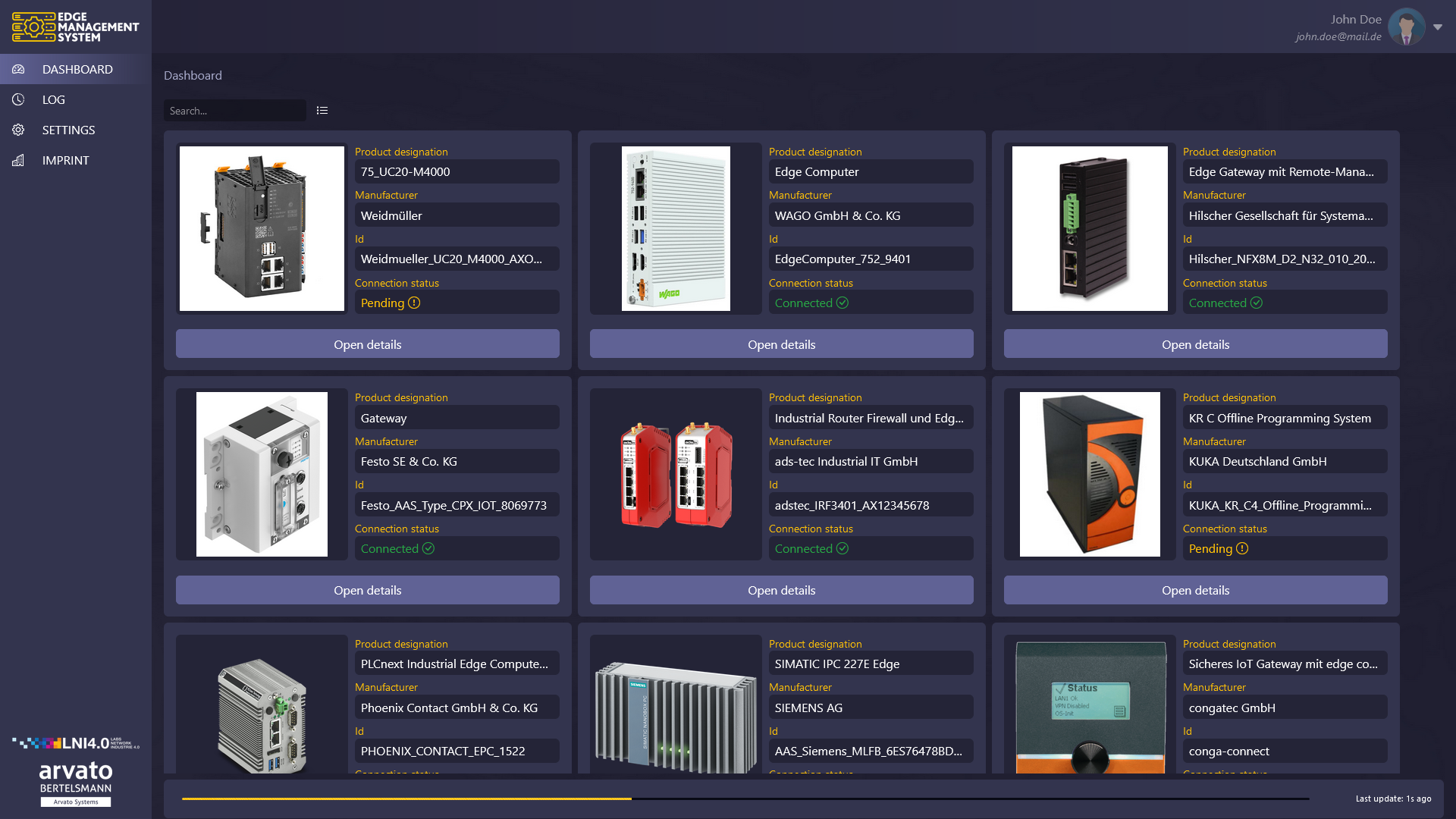

Dashboard

Dashboard of the Edge Management System as an overview of the various devices from different manufacturers

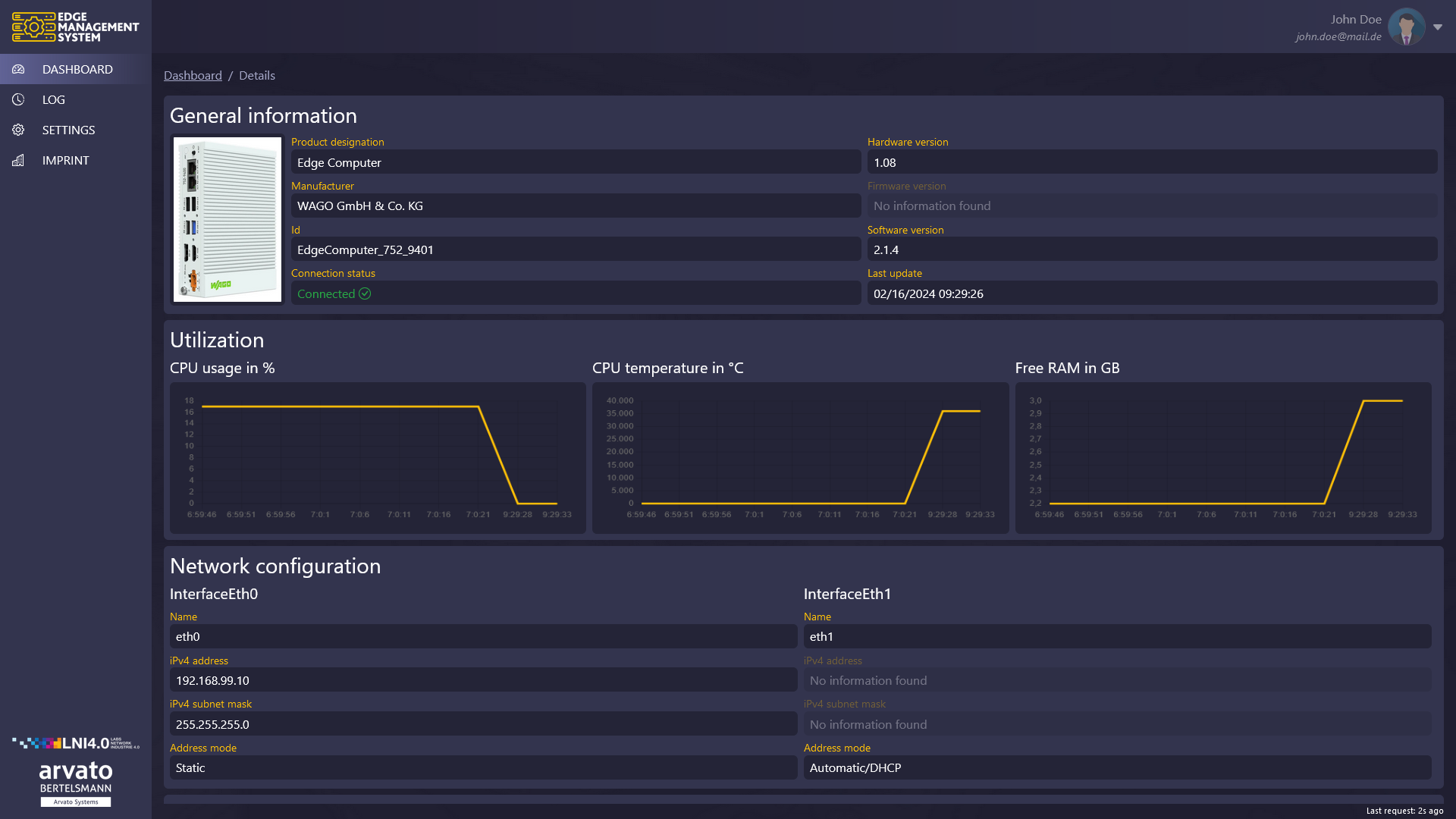

User Interface

User interface - overview of an individually selected device for various information, such as CPU utilization, temperature and firmware

The demonstrator's milestones include the successful management of edge devices from different manufacturers. It is also possible to display a wide range of information, such as "health information", from different edge devices via a standardized user interface (UI). In summary, the demonstrator makes it clear that cross-manufacturer management of edge devices is possible and holds great, as yet untapped potential for Industry 4.0.

Outlook

The constantly growing Internet of Things and edge computing landscape is accompanied by a promising increase in benefits for production companies. An interoperable edge management system makes it possible to manage heterogeneous edge resources efficiently in every respect, to adapt them flexibly and, if necessary, to optimize them in order to meet constantly changing requirements. Effective and genuine interoperability through a neutral interface for managing the various new and retrofitted edge devices is reason enough to further develop the project, transfer it to testing and thus promote innovation as a whole.

Written by